brand consulting

THE PATH TO A MORE SUSTAINABLE AND TRANSPARENT BUSINESS

See how we can support your company:

WE HELP YOUR COMPANY ACHIEVE ITS GOALS!

We support companies, manufacturers, and suppliers in making their materials and processes more sustainable and transparent. With technical guidelines and customized solutions, we ensure your products meet the highest environmental, social, and governance standards — adding value and credibility in the marketplace.

Our focus is on reducing impacts, optimizing processes, and turning sustainability into a competitive advantage — without compromising quality, performance, or economic feasibility.

life cycle

assessment

Environmental Product Declaration

KPIs MANAGEMENT FOR ESG REPORTING

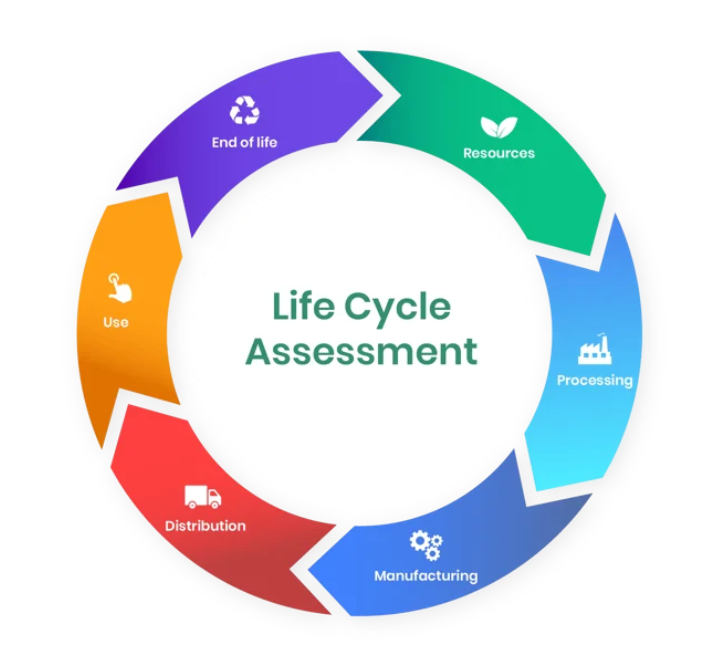

LIFE CYCLE ASSESSMENT (LCA)

Objective:

The Life Cycle Assessment (LCA) quantifies the environmental impacts throughout the entire production chain of a product. Through this analysis, clients can identify the materials and processes with the highest environmental impact, enabling the implementation of strategic improvements in both the production process and the supply chain.

Methodology:

Environmental impacts are calculated in accordance with ISO 14040 and ISO 14044 standards, ensuring technical rigor and reliability of results. To achieve this, we combine company-specific data with regional and global information from internationally recognized databases, ensuring a precise and comprehensive analysis.

Environmental Product Declaration (EPD)

Objective:

The Environmental Product Declaration (EPD) is the most comprehensive environmental label, offering transparency beyond the Life Cycle Assessment (LCA). Available on online platforms, the EPD provides public access to environmental information without disclosing the company’s strategic data.

Methodology:

The EPD is standardized by ISO 14025 and developed based on a combination of this standard with Product Category Rules (PCR), which are specific guidelines for each sector and/or product. This document requires an LCA that has undergone third-party critical review.

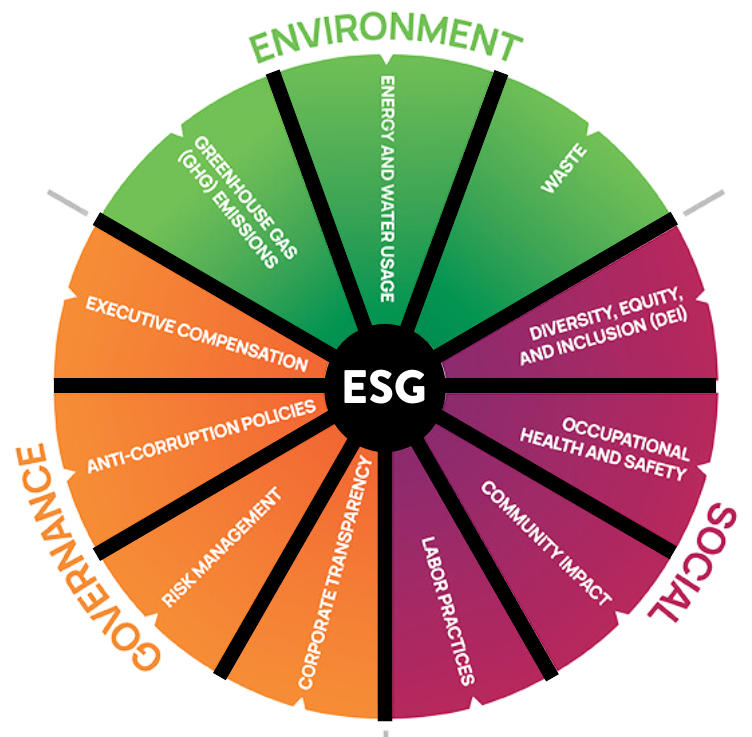

KPIs MANAGEMENT FOR ESG REPORTING

Objective:

The ESG KPI Management service helps companies measure, monitor, and communicate their environmental, social, and governance performance. With effective management, companies ensure transparency, meet regulatory requirements, strengthen stakeholder relationships, and adopt best sustainability practices.

Methodology:

Through interviews with key stakeholders from various departments, data is collected to build a solid foundation of performance indicators (KPIs), which are then compiled and used in annual sustainability reports and periodic disclosures.

meet some of our cases:

life cycle assessment - Grupo LAMOSA BRASIL

The partnership between Roca Brasil Cerámica and UGREEN began in 2019 with the Life Cycle Assessment (LCA) of products from the Campo Largo-PR factory. That same year, the company published its first Sustainability Report, now released annually.

In 2020, Roca became the first ceramic tile manufacturer to carry out an LCA in Brazil, expanding the study to its São Mateus do Sul factory in 2021. As a result, the company replaced petroleum coke with biomass for heat generation, becoming a reference in renewable fuel use. The company now uses wood industry residues, such as briquettes, repurposing discarded materials and reducing environmental impact.

KPIs MANAGEMENT - LINDT BRASIL

In 2023, UGREEN, in partnership with Grupo Ambiensys, had the opportunity to support Lindt Brazil in compiling KPIs for reporting indicators to the international headquarters. UGREEN acted as the focal point for organizing and processing data from Lindt Brazil's stores and logistics partners, ensuring standardization and compliance with international requirements.

With the support of a specialized ESG consultancy, Lindt Brazil was able to streamline data collection and management efficiently, ensuring greater accuracy and integration among all stakeholders involved.

CARBON FOOTPRINT - BAMBUSA ATELIER

Bambusa Atelier specializes in the creation of structures and projects using bamboo. For the 2024 Christmas events held in the cities of Maringá-PR and Cascavel-PR, the carbon footprint of the bamboo structures was calculated and compared to the carbon footprint the structure would have had if it were made of steel, a material traditionally used.

The analysis considered the life cycle of both materials, from raw material extraction to installation. The studies revealed that the use of bamboo avoided the emission of 295 tons of CO₂ equivalent in the Maringá event and 167 tons in the Cascavel event. To contextualize this impact, the avoided emissions are equivalent to approximately 1,300 round-trip car journeys between Curitiba and Maringá, and 650 round trips between Curitiba and Cascavel.

We are available for any further information and look forward to the opportunity to collaborate in your sustainable transformation

@2025 UGREEN All rights reserved I Terms of Use I Privacy